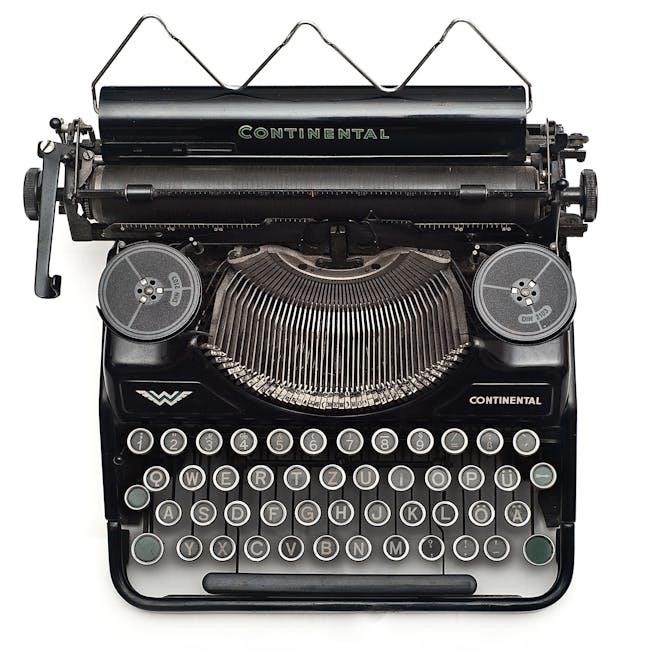

Continental O-200 Parts Manual: A Comprehensive Overview

This illustrated parts catalog details models C75, C85, C90, and O-200 engines, offering a searchable, bookmarked resource for mechanics and enthusiasts alike․

Available in English and compatible with both Windows and Mac, this manual provides essential information for Continental engine maintenance and overhaul procedures․

The Continental O-200 engine represents a cornerstone of general aviation power, renowned for its reliability and widespread use in numerous aircraft models․ This engine, along with its counterparts – the C75, C85, and C90 – benefits from a comprehensive parts manual designed to facilitate maintenance, repair, and overhaul procedures․

Understanding the intricacies of the O-200 requires access to detailed parts information, which is precisely what this manual delivers․ It serves as an invaluable resource for aviation mechanics, aircraft owners, and anyone involved in the upkeep of these engines․ The catalog meticulously lists components, providing part numbers and descriptions essential for accurate identification and ordering․

Whether performing routine maintenance or a complete overhaul, this manual ensures that the correct parts are utilized, maintaining the engine’s performance and safety standards․ It’s a critical tool for ensuring continued airworthiness and operational efficiency․

Scope of the Parts Manual

This Continental O-200 parts manual encompasses a detailed inventory of components for the C75, C85, C90, and O-200 engine families․ Its primary scope is to provide a definitive reference for identifying and sourcing replacement parts, streamlining maintenance and overhaul processes․ The manual doesn’t typically cover accessories or parts directly attached to aircraft manufactured under production model numbers; those are usually sourced from the aircraft manufacturer․

The catalog’s coverage extends to a wide array of engine internals and external components, presented in an illustrated format for easy comprehension․ It’s designed to be a complete resource, though users should verify accessory availability separately․

Available in both digital and USB formats, the manual aims to support both professional mechanics and DIY enthusiasts, offering a searchable and indexed system for efficient parts location․

Engine Models Covered

This parts manual comprehensively supports Continental engine models C75, C85, C90, and the O-200 series, providing detailed parts information for each configuration․

C75 Engine Parts

The Continental C75 engine parts catalog, integrated within the broader manual covering C75, C85, C90, and O-200 models, offers a detailed breakdown of each component․ This section meticulously lists all available parts, crucial for maintenance, repair, and overhaul procedures․

Information includes detailed illustrations and part numbers, enabling accurate identification and ordering․ The catalog specifies parts applicable to various C75 configurations, acknowledging that accessories might be sourced directly from the aircraft manufacturer if not listed․

Users can efficiently locate specific components using the searchable digital format, available on CD or USB, featuring both TIF images and an Adobe Acrobat version for easy browsing․ This ensures accessibility for professional mechanics and DIY enthusiasts alike, streamlining the parts procurement process for this classic engine․

C85 Engine Parts

The Continental C85 engine parts section, contained within the comprehensive catalog for C75, C85, C90, and O-200 engines, provides a complete inventory of components․ This detailed listing is essential for effective engine maintenance, accurate repairs, and thorough overhauls․

The catalog utilizes clear illustrations and precise part numbers to facilitate easy identification and ordering of necessary replacements․ It’s important to note that accessories or parts unique to aircraft installations may need to be sourced directly from the aircraft manufacturer if not explicitly included․

The digital format, accessible via CD or USB, offers a searchable and bookmarked experience, enhancing usability for both professional mechanics and hobbyists․ This streamlined access ensures efficient parts location and procurement for the C85 engine․

C90 Engine Parts

The Continental C90 engine parts listing, integrated within the broader catalog covering C75, C85, C90, and O-200 engines, offers a detailed breakdown of all engine components․ This section is crucial for performing accurate diagnostics, completing necessary repairs, and executing comprehensive overhauls of the C90 powerplant․

The catalog employs illustrative diagrams and specific part numbers – like those found in Form X-30011A – to simplify the identification and ordering process․ Users should verify accessory parts specific to aircraft models with the aircraft manufacturer if not listed․

The digital catalog, available on CD with Adobe Reader 7․0 or via USB, is fully searchable and bookmarked, providing quick access to the required information for both experienced mechanics and DIY enthusiasts․

O-200 Engine Parts

The O-200 engine parts section within this comprehensive manual is specifically tailored for the A, B, and C models of the Continental O-200․ It details over fifty individual parts recommended for replacement during a standard 100-hour overhaul, including precise quantities and descriptions for each component․

Utilizing Form X-30011, the catalog provides a clear pathway to identifying and procuring the necessary parts․ The illustrated format, presented through digitally cleaned TIF images, ensures accurate visual referencing․

Access to this information is streamlined through a searchable and bookmarked digital catalog, compatible with both Windows and Mac operating systems․ Remember to consult the aircraft manufacturer for accessories not explicitly listed․

Understanding the Parts Catalog

This catalog is available digitally for Win/Mac, offering searchable and bookmarked features for easy navigation․ It utilizes illustrated parts listings and Adobe Acrobat compatibility․

Illustrated Parts Catalog Format

The Continental O-200 parts manual employs a detailed, illustrated parts catalog format, presenting each component with corresponding diagrams for clear identification․ This visual approach significantly aids in accurate parts selection and assembly during maintenance or overhaul procedures․

Each illustration is meticulously crafted, showcasing exploded views of assemblies and individual parts, accompanied by descriptive labeling․ The catalog utilizes TIF images, digitally cleaned page by page, ensuring high clarity and detail․ Form X-30011A is central to this format․

This format isn’t merely visual; it’s integrated with a digital version in Adobe Acrobat, allowing for easy browsing and enhanced accessibility․ The combination of detailed illustrations and digital convenience makes this catalog an invaluable resource for both seasoned professionals and DIY mechanics working with Continental engines․

Digital Catalog Availability (Win/Mac Compatibility)

The Continental O-200 illustrated parts catalog is readily accessible in a convenient digital format, ensuring broad compatibility for users․ This catalog is specifically designed to function seamlessly on both Windows and Macintosh operating systems, eliminating platform-specific limitations․

Beyond standard computer access, the manual is also available on a USB drive, providing portability and offline access․ The digital version includes an Adobe Acrobat Reader version, with Reader 7․0 supplied on the CD, facilitating easy navigation and viewing of the detailed parts information․

This widespread compatibility ensures that mechanics and enthusiasts, regardless of their preferred operating system, can efficiently utilize this comprehensive resource for Continental engine maintenance and repair․

Searchable and Bookmarked Features

The Continental O-200 parts manual is engineered for efficient information retrieval, boasting robust searchable capabilities․ Users can quickly locate specific parts or diagrams by entering keywords, part numbers, or relevant descriptions directly into the digital catalog․ This feature dramatically reduces search time and streamlines the identification process․

Furthermore, the catalog is meticulously bookmarked and indexed, providing a structured navigation system․ This allows users to jump directly to specific sections or systems within the engine, eliminating the need for extensive scrolling or browsing;

These combined features – searchability and bookmarking – make the manual an invaluable tool for both professional mechanics and DIY enthusiasts, ensuring rapid access to critical parts information․

Key Components and Systems

This manual meticulously details the cylinder assembly, piston and connecting rod configurations, and the crankshaft with its accessory drive, crucial for O-200 maintenance․

Cylinder Assembly and Parts

The cylinder assembly is a critical component of the Continental O-200 engine, demanding precise parts identification and replacement during overhaul or maintenance․ This section of the parts manual provides detailed illustrations and part numbers for every element within the cylinder assembly․

Key components include the cylinder barrel itself, cylinder head, valves (intake and exhaust), valve guides, valve springs, retainers, and keepers․ Detailed breakdowns showcase the piston rings, wrist pin, and connecting link․ The manual also specifies gaskets and seals essential for maintaining compression and preventing oil leaks․

Accurate identification using part numbers like those found in Form X-30011A is paramount․ The catalog’s searchable and bookmarked features facilitate quick location of specific parts, ensuring efficient repairs and adherence to Continental’s specifications․ Proper assembly requires referencing the illustrated diagrams for correct orientation and torque values․

Piston and Connecting Rod Assembly

The piston and connecting rod assembly is fundamental to the O-200 engine’s power generation, requiring meticulous attention to detail during overhaul․ This section of the parts manual offers comprehensive breakdowns of each component, ensuring accurate parts selection and proper reassembly․

Key elements include the piston itself, piston rings (compression and oil control), wrist pin, wrist pin retaining rings, connecting rod, and connecting rod bearings․ The manual details specifications for piston-to-cylinder clearance and bearing tolerances, crucial for optimal performance and longevity․

Utilizing the illustrated parts catalog and searchable features, technicians can quickly locate specific part numbers, such as those listed in the 100-hour overhaul parts list for the O-200 A/B models․ Correct installation, referencing diagrams from Form X-30011A, is vital for maintaining engine reliability and preventing catastrophic failure․

Crankshaft and Accessory Drive

The crankshaft and accessory drive system are critical components within the Continental O-200 engine, demanding precise maintenance and accurate parts replacement․ This section of the parts manual provides detailed illustrations and part numbers for all related components, facilitating efficient overhaul procedures․

Key components include the crankshaft itself, main bearings, counterweights, and the accessory drive components like the oil pump drive, magneto drive, and vacuum pump drive․ The manual specifies critical tolerances for bearing clearances and crankshaft runout, ensuring smooth operation and minimizing vibration․

Accessing the digital catalog (Win/Mac compatible) allows technicians to quickly identify and order necessary parts, referencing the searchable database and utilizing part numbers like X30011․ Proper installation, guided by the illustrated diagrams, is essential for maintaining engine performance and adhering to overhaul standards․

Overhaul Parts Replacement

This document lists over fifty individual part numbers for a 100-hour overhaul of a Continental O-200 A/B engine, including descriptions and quantities․

100-Hour Overhaul Parts List (O-200 A/B)

The Continental O-200 A/B engine requires specific parts replacement during a 100-hour overhaul to ensure continued reliable operation․ This comprehensive list, detailed in the parts manual, encompasses over fifty individual part numbers crucial for maintaining engine integrity․

These replacements aren’t merely suggestions; they are essential components designed to prevent potential failures and uphold safety standards․ The list includes items like gaskets, seals, O-rings, and various hardware components subject to wear and tear during normal operation․

Proper adherence to this parts replacement schedule, as outlined in form X-30011A, is paramount for any mechanic performing the overhaul․ The manual provides detailed descriptions and the necessary quantities for each part, streamlining the process and minimizing errors․ Utilizing this list guarantees a thorough and effective overhaul, maximizing engine lifespan and performance․

Essential Parts for Overhaul

A complete Continental O-200 overhaul necessitates replacing more than just the items on the 100-hour list․ Essential components requiring attention include cylinder assembly parts, piston and connecting rod assemblies, and critical elements within the crankshaft and accessory drive systems․

Gaskets and seals throughout the engine are paramount, preventing leaks and maintaining proper compression․ Inspect and replace valve guides, valve springs, and retainers to ensure optimal valve train function․ Furthermore, careful examination of the camshaft and lifters is crucial, with replacement recommended based on wear assessment․

The illustrated parts catalog provides detailed diagrams and part numbers for each of these essential components․ Utilizing this resource, alongside the 100-hour overhaul list, guarantees a comprehensive and reliable engine rebuild, restoring performance and extending the engine’s service life․

Quantity and Description of Replacement Parts

The Continental O-200 A/B 100-hour overhaul typically requires replacing over fifty individual parts․ This includes a multitude of gaskets (cylinder head, oil pan, exhaust), seals (valve stem, crankshaft), and O-rings․ Quantities vary, but common items include multiple cylinder head bolts and nuts, alongside several piston rings per cylinder․

Essential replacements also encompass valve spring retainers, valve guides, and oil filter elements․ The catalog details specific quantities needed for each engine configuration․ Part descriptions are precise, referencing the component’s function and location within the engine․

Form X-30011A provides a comprehensive listing, ensuring accurate ordering and a complete overhaul․ Utilizing this detailed information minimizes downtime and guarantees a thorough restoration of the engine’s operational integrity․

Locating Specific Parts

Continental’s engine part search allows users to find components for the O-200․ Utilizing part numbers, like X30011, ensures accurate identification and ordering․

Continental Engine Part Search

The Continental Engine Part Search is a crucial tool for identifying and acquiring the correct components for your O-200 engine․ This system allows users to navigate a comprehensive database of parts, ensuring compatibility and proper fit․ To effectively utilize this search function, it’s beneficial to have your engine configuration readily available, as specific parts may vary based on model and serial number․

Alternatively, you can directly browse parts listed for the O-200 engine, exploring available options and detailed specifications․ The search functionality streamlines the process of locating even the most specialized components, reducing downtime and ensuring accurate repairs․ Remember to verify part numbers before ordering to guarantee the correct item for your specific application․ This dedicated search tool simplifies maintenance and overhaul procedures, providing a reliable resource for both professional mechanics and dedicated aircraft owners․

Using Part Numbers (X30011)

Part numbers, such as X30011, are fundamental to accurately identifying and ordering replacement components for your Continental O-200 engine․ This alphanumeric code uniquely designates each part, ensuring you receive the correct item for your specific application․ When referencing the parts manual or placing an order, always double-check the part number against the illustrated diagrams and descriptions․

The X30011 designation, for example, is associated with specific overhaul parts lists, like those for the O-200 A/B models, detailed in change notices (August 2011, Change 2)․ Utilizing these numbers eliminates ambiguity and minimizes the risk of ordering incorrect or incompatible parts․ Accurate part number usage is critical for successful engine maintenance, overhaul, and repair, contributing to the continued airworthiness and reliability of your aircraft․

Manual Updates and Revisions

Change notices, like the August 2011, Change 2 update, detail revisions and ensure access to the latest information regarding parts and procedures․

Change Notices (e․g․, August 2011, Change 2)

Continental issues change notices to reflect updates, corrections, and new part information within the O-200 parts manual․ These notices, such as the documented “August 2011, Change 2,” are crucial for maintaining accuracy and ensuring technicians utilize the most current data during maintenance and overhaul procedures․

These revisions may encompass part number updates, superseded components, or clarified installation instructions․ Regularly checking for and applying these change notices is paramount to avoid using outdated information that could compromise engine reliability or safety․ Accessing these updates guarantees compliance with Continental’s latest engineering specifications․

Operators should diligently track change notice dates and implement the corresponding revisions into their physical or digital manuals․ Ignoring these updates can lead to incorrect parts ordering, improper installation, and potentially, catastrophic engine failure․ Staying current with change notices is a fundamental aspect of responsible engine maintenance․

Accessing the Latest Information

Continental provides several avenues for accessing the most up-to-date O-200 parts manual information․ The illustrated parts catalog is available both in a traditional CD-ROM format, featuring TIF images and an Adobe Acrobat version for easy browsing, and increasingly, through digital platforms․

Authorized Continental Motors Parts distributors are a primary source for obtaining current manuals and change notices․ Additionally, the Continental website often hosts downloadable updates and revisions․ Utilizing the Continental Engine Part Search tool allows users to verify part eligibility and access relevant documentation․

Subscribing to Continental’s service bulletins and technical publications ensures timely notification of critical updates․ Regularly checking these resources is vital for maintaining accurate records and performing safe, effective engine maintenance․ Proactive information gathering guarantees technicians work with the latest approved data․